Your cart is currently empty!

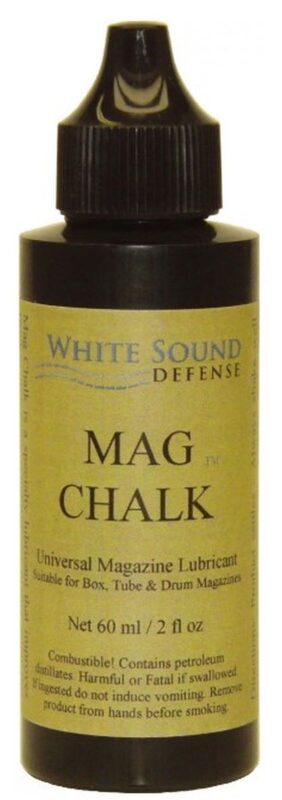

White Sound Defense Mag Chalk

$8.95

3 in stock

Description

Mag Chalk is a specialty lubricant designed to improve the reliability of firearms by reducing magazine related failures. This purpose-formulated lubricant does not hold grit, is waterproof, and is engineered to effectively lubricate the types of fouling that are most likely to cause malfunctions. It will not contribute to corrosion like graphite or molybdenum disulfide (moly). It goes on wet and dries to a chalky film that ‘sheds’ as it comes into contact with particles of grit. It is suitable for use in all temperature ranges down to -40C. It is ideal for lubricating all types of magazines including tube, box, drum, etc.

Poorly functioning magazines are one of the most common causes of malfunctions in modern firearms. In sandy environments friction and fouling can cause rounds to advance sluggishly, resulting in a slide or bolt over-ride. In severe cases the follower may bind or jam preventing the magazine from feeding at all. In cold weather environments frost can form inside a magazine causing it to jam. A proper lubricant can greatly increase the environmental tolerance of the magazine.

Traditional wisdom has been that little or no lubrication should be applied to magazines to avoid attracting dirt and grime. This concern it understandable as experience has shown that even supposedly ‘clean’ lubricants fail to function correctly in a magazine. And unfortunately, the few that do avoid attracting grit, lack the ability to effectively lubricate the larger particles that cause most malfunctions.

Up until now the best option was to use powered lubricants such as graphite or molybdenum disulfide (moly) in an effort to get effective lubrication in magazines. However graphite, while a decent lubricant, encourages galvanic corrosion in steel and aluminum, so to some degree you are trading one problem for another. On the other hand, moly tends to cause acidic corrosion on surfaces it is in contact with. Neither is an ideal solution and neither holds up particularly well in wet environments.

The solution developed by White Sound Defense is a liquid product that dries to a thick waterproof semi-solid film that ‘sheds’ as it comes into contact with particles of grit. It is unlike any grease or lubricant used for general firearm lubrication. The product also forms a thinner highly durable lubrication film that bonds to the internals of the magazine itself.

Mag Chalk was designed and developed start to finish to do one job – reduce magazine related malfunctions no matter what the environment.

Directions:

Product settles – Always shake well before applying. Start with a clean and empty magazine. Apply a total of 10-20 evenly spaced drops of Mag Chalk around the edges of the follower. Attempt to get the lubricant between the sides of the follower and walls of the magazine. Lightly depress the follower a few times to help spread the lubricant. Load the magazine. The lubricant will dry to a white film.

FAQ:

Q: Aren’t magazines supposed to be run unlubricated?

A. It is true that standard gun oil is not recommended for magazines. However, various specialty lubricants have been used in magazines to improve reliability for over 100 years. Manufacturers of drum magazines often provide dry lubricants to improve reliability. Silicone based wet lubricants are used by various artic warfare units to prevent frost from jamming magazines. Most magazines will run without lubrication, but they will run better with it. The more hostile the environment, the greater difference proper lubrication makes. In 2007 the Army ran a dust chamber test and 27% of the weapon stoppages were attributed to magazine malfunctions. Many of these stoppages would have been prevented by lubrication. Lubricating magazines is not a new idea. The issue has always been one of finding a suitable lubricant.

Q: How does molybdenum disulfide (moly) cause corrosion?

A: Moly contains sulfur in a form that produces a weak sulfuric acid when combined with water. In the field this water can come from condensation, sweat, rain, or humidity in the air. The weak acid attacks the metal and accelerates corrosion. A moly and water mixture can cause surface roughness on most steels within 24 hours.

Q: How does graphite cause corrosion?

A: Graphite causes corrosion in metals through a mechanism called galvanic corrosion. Galvanic corrosion is an electrochemical process in which one metal causes corrosion in another. It occurs when dissimilar metals are in electrical contact while in the presence of an electrolyte, such as water. The electrolyte can be from atmospheric humidity, sweat, or other sources. Graphite is on the extreme cathodic end of the galvanic series and will cause corrosion in nearly all metals.

Additional information

| Weight | 5 oz |

|---|